The decision to sign up to one of New Zealand’s most successful regional Lean training programmes has proved a winning one for all six Southland businesses.

Venture Southland’s Lean Management Programme, delivered by renowned Lean Thinking expert Clinton Yeats, is now in its 5 th year running. The six participants, from around the region, came together recently in Invercargill, to present their progress at the conclusion of the six-month intensive training programme. Venture Southland Group Manager Enterprise and Strategic Projects Steve Canny says that previous Southland participants in the Lean programme have seen an average productivity increase of 25% across their operations following the completion of the two year rollout plan; some have reported productivity increases as high as 70%.

Pypers Produce’s Brent Lamb & Brendan Hamilton Photo: supplied

“We are seeing some amazing results within Southland businesses. It’s not only the tremendous savings in day to day operations but also in the business linking and networking opportunities between Southland businesses that have undertaken the Lean programme.” Pypers Produce’s Brendan Hamilton says he and co-owner Brent Lamb asked around about the Lean Management Programme and were soon convinced of the benefits it could bring to their operation.

“We are now highly tuned to the whole lean process, identifying waste and implementing clear process within the business is now second nature. Staff feedback is positive and we are already seeing productivity improvement.

“Lean is an ongoing journey well worth taking, we highly recommend businesses sign up to the programme.” NES (Network Electrical Servicing) CEO Gavin Harris is also a 2016 lean convert. Gavin had identified that there was work within the organisation that needed to be undertaken but they had no process to implement.

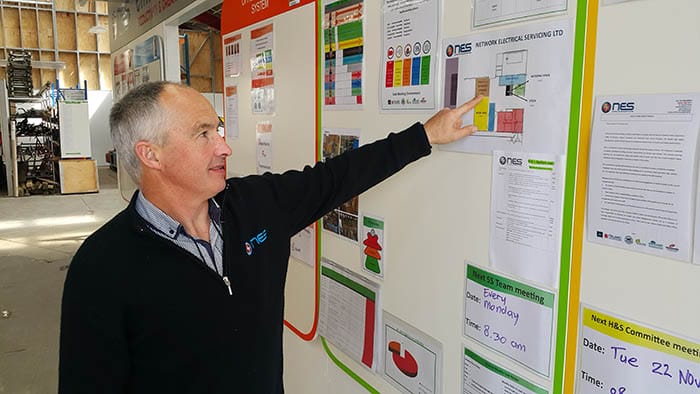

NES (Network Electrical Servicing) CEO Gavin Harris Photo: supplied

“We just didn’t know where or how to make a start, the programme provided us with the ability to identify areas for improvement and cut down on the waste within our processes.”

“Our Invercargill workshop had so much clutter that after we eliminated it we walled off the cleared section of the workshop and rented it out to another business. We’re on the way to attaining an efficient workplace plus we’re generating revenue from space created by becoming more efficient.”

“I only wish we had undergone the Lean programme earlier and would recommend other businesses undertake the programme.” Lean programme trainer Clinton Yeats says Lean is a way of thinking and a way of working in an organisation.

“Process is the way in which we work, most of us are not process thinkers, what that means is that we are outcome thinkers. Most people go to work thinking of achieving an outcome, thinking Lean teaches us to be process thinkers – to design the most efficient quality driven process, to get it right first time every time. Focusing in on how we work is what Lean is all about”

“The other thing is environment. A person’s productivity or output is entirely dependent upon the environment in which they work. A big part of the Lean programme is about improving the physical environment we call this 5S.”

Applications are now open for the 2017 Lean Management Programme Venture Southland is calling on Southland businesses who think they are up for the challenge of going Lean in 2017 to get in touch with Rachel Butler, Lean Management Programme Coordinator at Venture Southland.

Participating businesses 2016:

- Phoenix Services

- NES

- Vet South

- Retro Organics

- Pypers Produce

- Lewis Windows